SWEP Heat Exchanger Gasket

SWEP Gaskets Types

-

-

- SWEP G102

- SWEP G108

- SWEP G153

- SWEP G157

- SWEP G158

- SWEP G234

- SWEP G52

- SWEP G58

- SWEP G65

- SWEP GC65

- SWEP GF138

- SWEP GF257

- SWEP GF276

- SWEP GF59

- SWEP GX100

- SWEP GX12

- SWEP GX18

- SWEP GX26

-

-

-

- SWEP GX42

- SWEP GX51

- SWEP GX64

- SWEP GX91

- SWEP HX145

- SWEP HX180

- SWEP HX205

- SWEP HX25

- SWEP HX265

- SWEP HX50

- SWEP HX85

- SWEP MF138

- SWEP MF257

- SWEP MF276

- SWEP MF56

- SWEP MF59

- SWEP UX10

- SWEP UX80

-

Which are non-OEM gaskets 100% compatible with gaskets manufactured by SWEP.

SWEP has various advantages including optimization of energy, materials, and space in cooling and heating systems. They pursue to contribute to a comfortable and sustainable life for people around the world and competitive edge for their customers. SWEP is part of the global Dover Corporation. They offer extensive expertise with the widest product range on the global market and a modular concept that enables for customization and optimization of the solutions.

PHE Nordic provides services and non-OEM spare parts for SWEP PHE Plate Heat Exchangers, and a wide range of international brands.

Plate Heat Exchanger Plates, Gasketed Plate Heat Exchanger, Plate Heat Exchanger Gaskets, or Fresh Water Generators spares.

Heat Exchangers Gaskets:

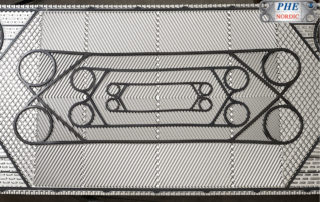

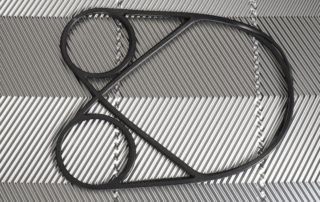

The process of formulating the right gasket compound and profile for a specific duty or application is considered an art or a science itself to be more accurate. For instance, the process to compound the right rubber mixture can involve the selection of anywhere from five to fifteen different substances from around 1700 of different grades of polymer, vulcanizing chemicals and processing materials currently available. This selection process can be influenced by a host of other parameters that could affect the eventual performance of the gasket. The final choice of materials used can be determined by the actual nature of the duty and the interaction between the gasket material and the plates all individually and collectively, working environment, the service temperature and pressure. Gaskets are molded in one piece, materials normally an elastomer, to be selected to suit the actual combination of chemical environment, temperature and possible other conditions to be considered. One-piece gasket is consisting of one field gasket, two ring gaskets and links.

Contact our sales team today for further information and offers:

- E-mail: phe@phe-nordic.com End Users

- E-mail: newphe@phe-nordic.com Wholesalers/Dealers

- Phone: +45 70 202 303

Heat Exchanger Gasket Materials:

NBR – NITRIL – VITON fluoroelastomer – EPDM – NBRHT – NITRIL high temp