PHE Nordic is your service partner for Plate Heat Exchangers and Fresh Water Generators

Plate Heat Exchanger Maintenance

PHE Nordic is your partner within service, reconditioning and cleaning of Plate Heat Exchangers and Fresh Water Generators service.

We offer Plate Heat Exchangers repair services, whether it is big or small Plate Heat Exchanger.

Plate heat exchanger service includes:

Cleaning Plate Heat Exchanger

Chemical Cleaning Heat Exchanger Plates

Your service provider of Heat Exchanger Chemical Cleaning and Refurbishment

Offshore- Marine- Power Plants- Food- Pharmaceutical- Chemical- Industry- HVAC- District heating and District cooling

Benefits when using PHE Nordic as your Plate Heat Exchanger service provider:

- Fast and reliable service ensures your Plate Heat Exchanger returns with optimum performance as fast as possible.

- Our cleaning facility combined with our experienced service team is one of the most efficient in Europe.

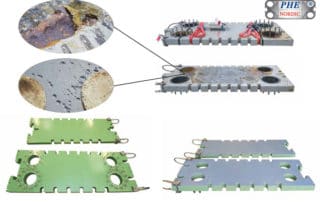

- Chemical cleaning plate heat exchanger, using plate heat exchanger cleaning chemicals removes, all scaling and fouling effectively from both plates and frame.

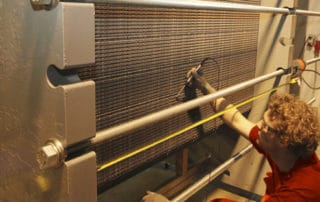

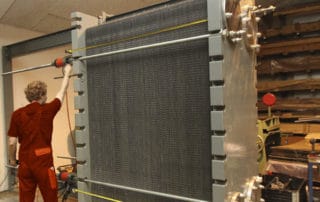

- Experienced and highly qualified service technicians available for onsite disassembling and assembling of Plate Heat Exchangers.

- Heat Exchanger leak detection method, Dye-penetration or Helium heat exchanger leak test reveals even the smallest pinholes on the plates.

- We have the most common used gaskets and plates in stock, if spare part replacements are required.

- Our service team can repress deformed gasket tracks.

- Our service team mounts new gaskets and provide a pressure test of the plate pack in our own or customer’s frame, at our facility or onsite.

- Oil cooler cleaning service.

- We also offer cleaning of marine heat exchanger.

Interance Control

Cleaning Heat Exchanger Plates / plate to plate heat exchanger cleaning procedure.

Heat Exchanger Chemical Cleaning

Leak Detection method Dye Penetration and Helium

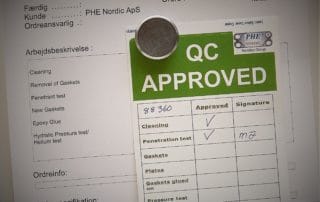

Quality control and assurance is not just something we say – It is something we do..

PHE Nordic has a quality system, which step-by-step documents, all inspections, service and repair, that has been completed during each case.

Systematic maintenance pays off

Systematic maintenance of your Plate Heat Exchangers has direct relation to both the energy and production cost, because of reduced power consumption to auxiliary equipment, e.g. pumps.

We, at PHE Nordic, will assist and support you creating systematic maintenance process to heat exchangers.

Helium Leak Testing Heat Exchanger

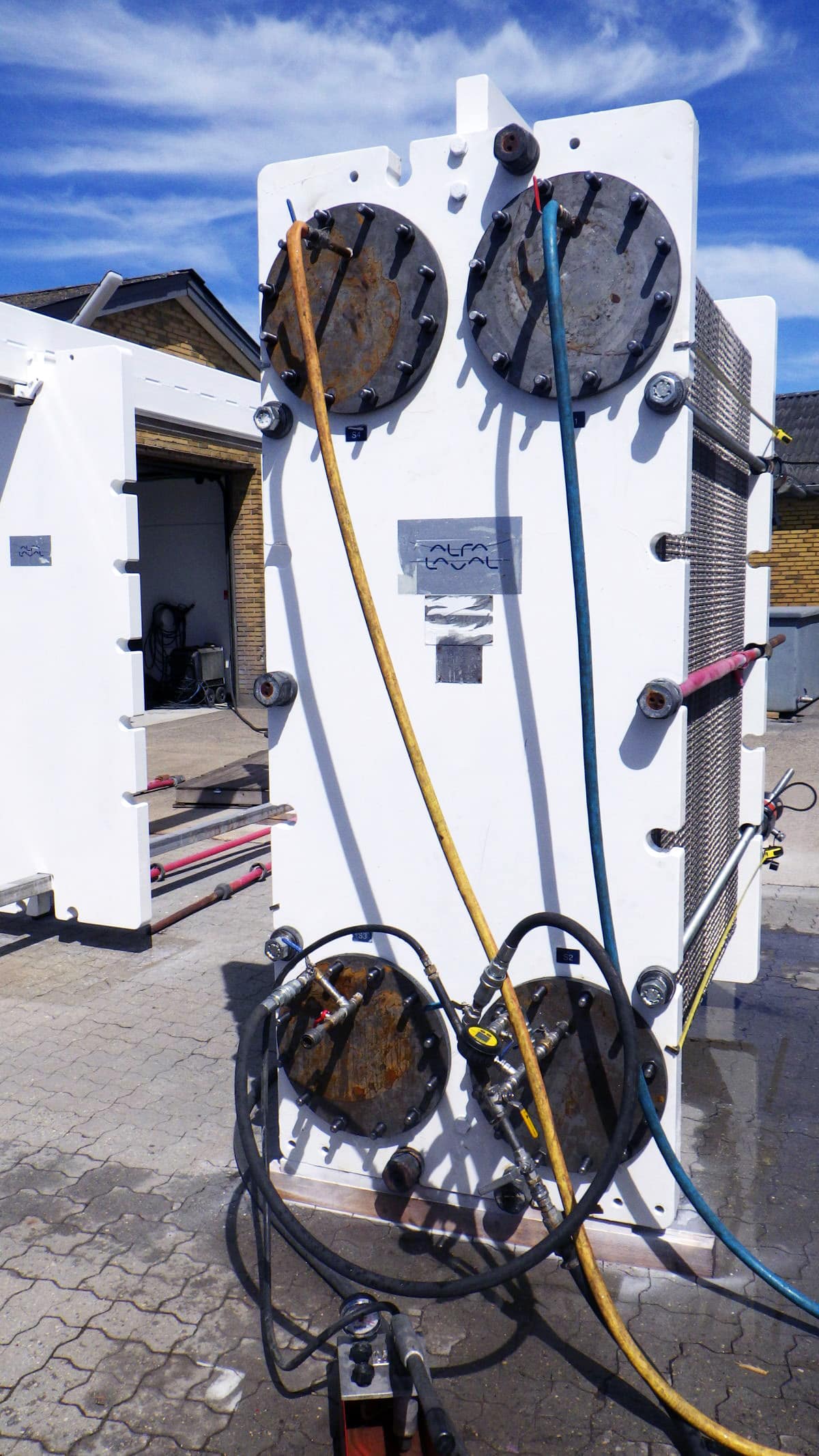

Plate Heat Exchanger Pressure Test

Pressure Testing

Pressure Testing of Plate Packs and complete Plate Heat Exchangers Services:

As a final control of refurbished plate packs and complete Plate Heat Exchangers, PHE Nordic offers pressure testing of the unit. This will ensure a trouble-free commissioning of the Plate Heat Exchanger at the installation site.

Pressure Testing Heat Exchangers

Your benefits using PHE Nordic as your service provider:

- Pressure testing of refurbished plate packs in frame for the most sold Plate Heat Exchanger types.

- Pressure testing of complete Plate Heat Exchangers after refurbishment.

- Plate Heat Exchanger leak detection in frame with Helium checking for micro-cracks in refurbished plate packs.

- A-measurement provided for the refurbished, pressure tested plate pack.

- Pressure Test Certificate with all testing data provided.

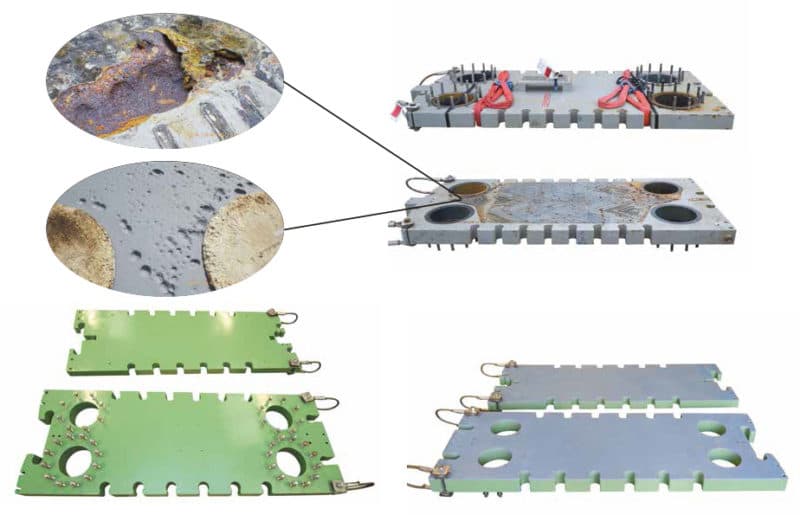

Plate Heat Exchanger Refurbishment

Frames Reconditioning

Refurbishment of Plate Heat Exchanger Frames

Your benefits using PHE Nordic as your service provider:

➤ Refurbishment of frames with corrosion damages is considerably cheaper, than purchasing new frames.

➤ The processes and procedures of refurbishment of frames are well documented.

➤ Sand-blasting for removal of damaged coating and corrosion.

➤ We use pyrolysis treatment to decompose and evaporate organic salt from the metal.

➤ Outer surfaces are FBE-coated to protect against future corrosion.

➤ Corrosion damages are built up with Nordtec Ceramic Rapid and the subsequently surface treated with Nordtec Ceramic Coating.

➤ After the coating, every surface of the frame is extremely protected against impact from harsh environments, e.g. in marine, offshore and chemical applications.

Following images show PHE frames before, during and after the refurbishment process utilizing sand-blasting, pyrolysis treatment, building up corrosion damages and the final FBE coating.

Frame before and after Reconditioning

Safety data sheets for glue:

Instruction for use:

PHE Nordic Cleaning Agent:

Cleaning of gasket track removing dirth, old glue, pieces of old gasket, and finally using the Degrease Agent to degrease the gasket track before gluing on new gasket.

Degrease agent

1 Litre Unit

Plate Type Heat Exchanger Maintenance

PHE Nordic repairs frame and plates for all types of Plate Heat Exchangers including:

- Fresh water generators

- Central coolers / LT coolers

- Lube oil coolers

- HT coolers

- Crude oil coolers

- Production oil coolers

- Gas coolers

- Condensers

- Fuel oil heaters

- Tank cleaning heaters

- MGO coolers

- Steam coolers

- Engine coolers

- Gear oil coolers

- Evaporators

- Plates coolers

Contact our sales team today for further information and offers:

- E-mail: phe@phe-nordic.com End Users

- E-mail: newphe@phe-nordic.com Wholesalers/Dealers

- Phone: +45 70 202 303