Hisaka Heat Exchanger Plates

Hisaka Plates Lists

-

-

-

- Hisaka EX11

- Hisaka EX11A

- Hisaka EX15

- Hisaka EX15A

- Hisaka EX16

- Hisaka GX40

- Hisaka GX40L

- Hisaka LX00A

- Hisaka LX10

- Hisaka LX10A

- Hisaka LX20

- Hisaka LX20A

- Hisaka LX30A

- Hisaka LX325A

- Hisaka LX40

- Hisaka LX40A

- Hisaka LX50A

- Hisaka LX525A

- Hisaka LX526B

- Hisaka RX10A type11

- Hisaka RX10A type13

- Hisaka RX11A

- Hisaka RX13A

- Hisaka RX30A

- Hisaka RX70

- Hisaka SX40 type41

-

-

-

-

-

- Hisaka SX40 type43

- Hisaka SX40A type41

- Hisaka SX40A type43

- Hisaka SX41

- Hisaka SX41A

- Hisaka SX43

- Hisaka SX70A

- Hisaka SX90

- Hisaka SX90M

- Hisaka UX01

- Hisaka UX10

- Hisaka UX100

- Hisaka UX10A

- Hisaka UX130

- Hisaka UX20

- Hisaka UX20A

- Hisaka UX226

- Hisaka UX30

- Hisaka UX30A

- Hisaka UX40

- Hisaka UX40A

- Hisaka UX80

- Hisaka UX80 type 81

- Hisaka UX90

- Hisaka YX80

-

-

Which are non-OEM plates 100% compatible with plates manufactured by Hisaka.

Hisaka offers thermal solutions that are based on the core technologies of the PHE. In 1953 they developed the first plate heat exchanger in Japan. Hisaka´s challenging spirit during their struggle to make unique development continues to flourish by creating new technologies and products. The heat exchanger division was formed in 2006 by merging the heat exchanger division, plate heat exchanger division, and the industrial equipment division.

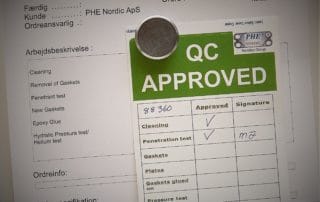

PHE Nordic provides services and non-OEM spare parts for Hisaka Plate Heat Exchangers, and a wide range of international brands.

Plate Heat Exchanger Plates, Gasketed Plate Heat Exchanger, Plate Heat Exchanger Gaskets, or Fresh Water Generators spares.

Heat Exchanger Plates:

Transferring Heat should involves bringing two substances at different degrees of temperatures to each other, so that one either cools or heats the other. In a way that energy already within the system and is transferred to another part of the process where it can be used for another effect. This process will save money and energy, and reduce environmental impact of the production process. Plates of heat transfers are characterized by optimum embossing, resulting in high heat transfer coefficients.

How to select the plate:

Heat transfer plates are supplied as standard in material grade AISI304, AISI316L, Titanium, Titanium-Pd, SMO254, Hastelloy respectively, due to its corrosion-resistance and easy cleaning.

Contact our sales team today for further information and offers:

- E-mail: phe@phe-nordic.com End Users

- E-mail: newphe@phe-nordic.com Wholesalers/Dealers

- Phone: +45 70 202 303

Titanium – AISI 316/304 – SMO – Hastelloy

In high or low thermal pattern