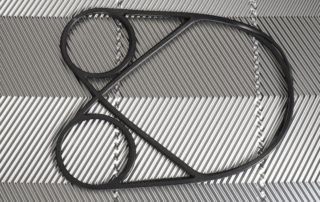

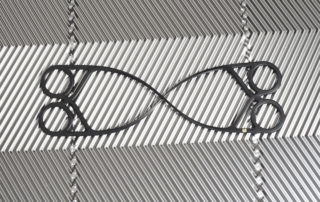

Fischer Heat Exchangers Gasket

Fischer Gaskets Types

-

-

- Fischer E5

- Fischer E8

- Fischer E18

- Fischer E28

- Fischer E28PI

- Fischer E40

- Fischer E40PI

- Fischer E100

-

Which are non-OEM gaskets 100% compatible with gaskets manufactured by Fischer.

Fischer US, LLC is affiliated with the Austrian company Fischer Maschinen und Apparatebau GmbH founded in 1933. They were pioneers in the manufacturing of Plate Heat Exchangers for food industry. Research and development for Fischer’s products is helping them to maintain their position worldwide with regard to reliability and quality. Fischer’s plate heat exchanger is developed and optimized for food and beverages heat transfer needs but their applications are not only limited to those industries. There are applications in water purifying systems, desalination systems, steam condensers, salt production, and many other applications has been very successful. This is why Fischer plate heat exchangers are leading in the heat transfer solutions. Many different designs of plates allows the selection of the most efficient heat transfer and the optimum product flow. Numerous types of materials are used for the plates and gaskets that can meet almost any requirements of processed products. Fischer plate heat exchangers have many ways to be configured, so to optimize the use of energy and comply with tight process parameters with precision to ensure quality control.

PHE Nordic provides services and non-OEM spare parts for Fischer Plate Heat Exchangers, and a wide range of international brands.

Plate Heat Exchanger Plates, Gasketed Plate Heat Exchanger, Plate Heat Exchanger Gaskets, or Fresh Water Generators spares.

We can mention here some of the benefits of Fischer Plate Heat Exchangers:

➤ Made to highest quality in the industry and have the best value.

➤ Design and manufacturing of plates can be customized upon request.

➤ Stability degree is the highest.

➤ Gaskets for installation with adhesive and press gaskets.

➤ Materials for chemically aggressive liquids and food-proof materials.

➤ CIP clean in place compatible, easy to clean.

➤ Low in maintenance cost.

➤ Various profiles of plates/gaskets for different needs.

➤ Longer lifetime.

Contact our sales team today for further information and offers:

- E-mail: phe@phe-nordic.com End Users

- E-mail: newphe@phe-nordic.com Wholesalers/Dealers

- Phone: +45 70 202 303

Heat Exchanger Gasket Materials:

NBR – NITRIL – VITON fluoroelastomer – EPDM – NBRHT – NITRIL high temp