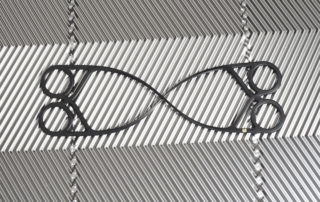

Vicarb Heat Exchanger Gaskets

Vicarb Gaskets Types

-

-

- Vicarb V100

- Vicarb V110 RT

- Vicarb V120

- Vicarb V13

- Vicarb V13 DW

- Vicarb V13 Snap

- Vicarb V130

- Vicarb V130 Snap

- Vicarb V180

- Vicarb V20

- Vicarb V20 Snap

- Vicarb V20 DW

- Vicarb V260

- Vicarb V28

-

-

-

- Vicarb V28 Snap

- Vicarb V4

- Vicarb V45

- Vicarb V45 Snap

- Vicarb V45 DW

- Vicarb V4 DW

- Vicarb V55

- Vicarb V60

- Vicarb V60 DW

- Vicarb V7

- Vicarb V85

- Vicarb VU12

- Other gaskets

-

Which are non-OEM gaskets 100% compatible with gaskets manufactured by Vicarb.

In the late 90´s Alfa Laval took over Vicarb and closed the production of Vicarb plate heat exchangers. However, there are still many Vicarb heat exchangers in many industries and it is still possible to purchase gaskets and plates at PHE Nordic.

PHE Nordic provides services and non-OEM spare parts for Vicarb Plate Heat Exchangers, and a wide range of international brands.

Plate Heat Exchanger Plates, Gasketed Plate Heat Exchanger, Plate Heat Exchanger Gaskets, or Fresh Water Generators spares.

When optimizing a Plate Heat Exchanger and achieve improvement, there are two main factors to be aware of: First the amount of heat transfer and the pressure drop have to be considered. Second, the Plate Heat Exchanger geometry is an important factor for the heat transfer and the pressure drop. The higher heat transfer and the less pressure drop are usually targeted. For the industrial applications affected by the pressure drop, the Plate Heat Exchangers shape is very important.

Plate Heat Exchangers gaskets: To compound the right rubber mixture, involves a complicated selection process. The working environment, the service temperature and pressure and the interaction between the gasket material and the plates all, helps to determine the final choice of used materials. Normally material is elastomer, to suit the actual combination of temperature, chemical environments and possible other conditions to be considered.

Benefits using non-OEM gaskets from PHE Nordic A/S

– Same as the original, but lower cost

– Full traceability of the gasket material, no matter what type of material

– Quality assurance before shipment, including measurement of gaskets and visual inspection

– PHE Nordic’s team has more than 20 years of experience and know-how within Plate Heat Exchangers and Fresh Water Generators

Contact our sales team today for further information and offers:

- E-mail: phe@phe-nordic.com End Users

- E-mail: newphe@phe-nordic.com Wholesalers/Dealers

- Phone: +45 70 202 303

Heat Exchanger Gasket Materials:

NBR – NITRIL – VITON fluoroelastomer – EPDM – NBRHT – NITRIL high temp