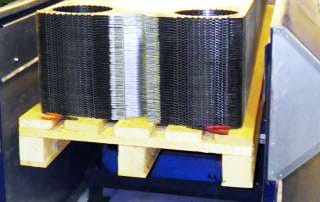

Plate Heat Exchanger Plates

PHE Nordic provides plates and services for a wide range of international Plate Heat Exchanger brands

Heat Exchangers Plate Brands:

PHE Nordic plates/gaskets are non-OEM, 100% compatible with genuine parts.

What is a plate heat exchanger ?

A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a conventional heat exchanger, because the fluids are exposed to a much larger surface area, since the fluids are spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change. Plate heat exchangers are now common and even small brazed versions are used in the hot-water sections in millions of combination boilers. The high heat transfer efficiency for such a small physical size has increased the domestic hot water (DHW) flowrate of combination boilers. The small plate heat exchanger has made a great impact in domestic heating and hot-water. Larger commercial versions use gaskets between the plates, whereas smaller versions tend to be brazed.

PHE Nordic provides services and spare parts for various numbers of Plate Heat Exchangers (PHE) – Heat exchanger (HEX) – Plate and Frame or Gasketed plate heat exchanger (GPHE) to a wide range of international brands.

Let us optimize your plate heat exchanger’s efficiency!

When improving the efficiency of your plate heat exchanger, you will maximize production, minimize energy consumption and be more environmentally friendly.

Plate Heat Exchangers are daily performing many critical duties for many different applications worldwide. Stainless steel plates and the alloy plates units are performing critical duties in petrochemical and chemical plants. The Titanium plates are used in variety of seawater cooling due to its advantage of space saving on shipboards.

Plates for Heat Exchanger, gasketed Plate Heat Exchanger, gaskets for Plate Heat Exchanger, or Fresh Water Generators.

When it comes to the design of the Plate Heat Exchangers, stainless steel is often used for the plates, due to its ability to withstand high temperatures, strength, and corrosion resistance. The selection of appropriate Plate Heat Exchanger depends on different factors, the system designer should consider the design limitation of the heat exchanger type, and cost of heat exchanger is often a primary factor, with several other selection factors such as:

- Thermal performance

- High/low pressure limits

- Product mix: liquid/liquid

- Temperature ranges

- Pressure drop through the exchanger

- Maintenance and repair

- Ease of expansion

- Type of materials required for construction

- Selection of material for frame and plates, such as aluminum, carbon steel, stainless steel, nickel alloys, and titanium.

Benefits using non-OEM plates from PHE Nordic A/S

➤ Same as the original, but lower cost.

➤ Full traceability of the plate material, no matter what type of material.

➤ Quality assurance before shipment, including measurement of plates and visual inspection.

➤ PHE Nordic’s team has more than 20 years of experience and know-how within Plate Heat Exchangers and Fresh Water Generators.

Contact our sales team today for further information and offers:

- E-mail: phe@phe-nordic.com End Users

- E-mail: newphe@phe-nordic.com Wholesalers/Dealers

- Phone: +45 70 202 303